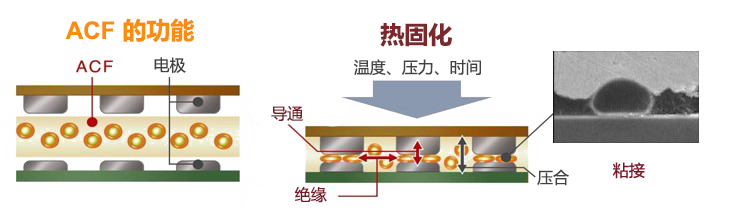

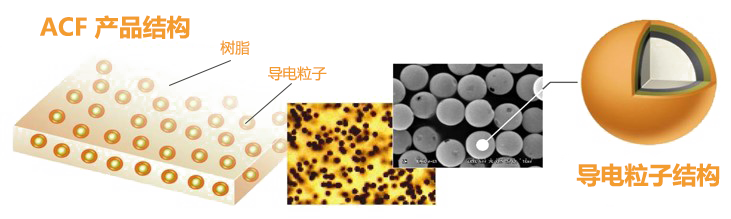

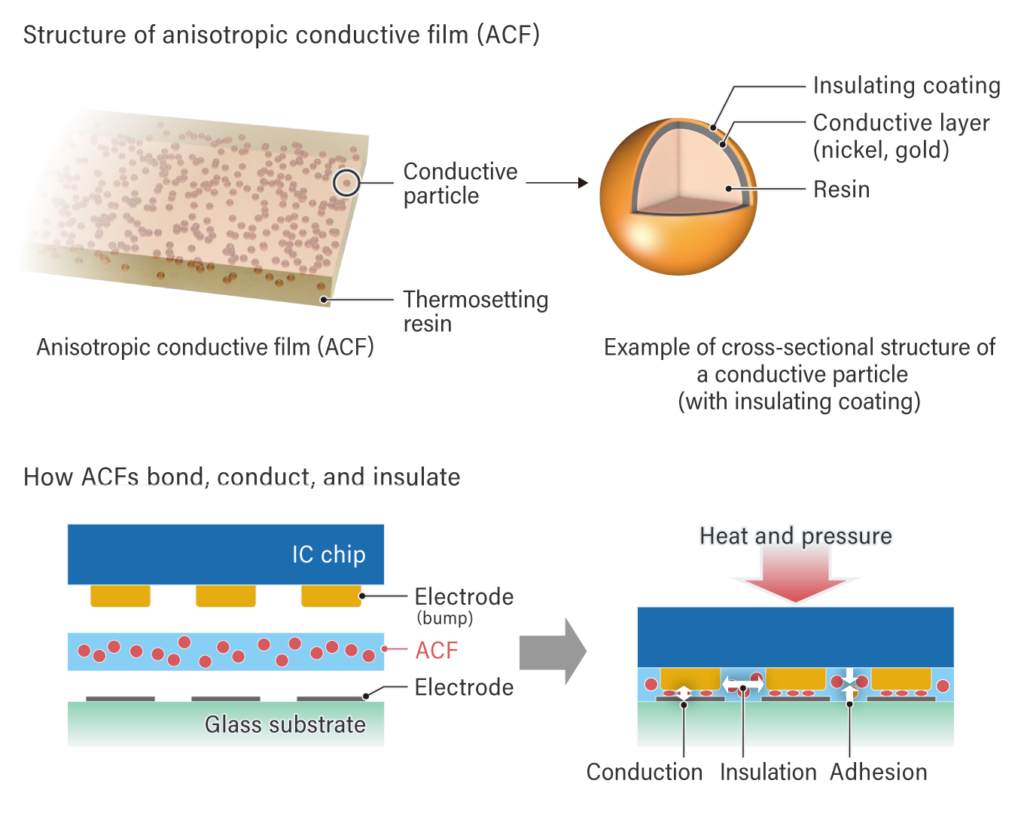

ACF (Anisotropic Conductive Film) is a TFT LCD LCDACF is a bonding film with conductive particles uniformly distributed in a heat-cured resin, which, when heated and pressurized, enables the electrodes to conduct in batches. Compared with solder or connector, ACF also has the advantages of small package area and Fine Pitch connection. It can simultaneously perform the functions of bonding, conduction and insulation.

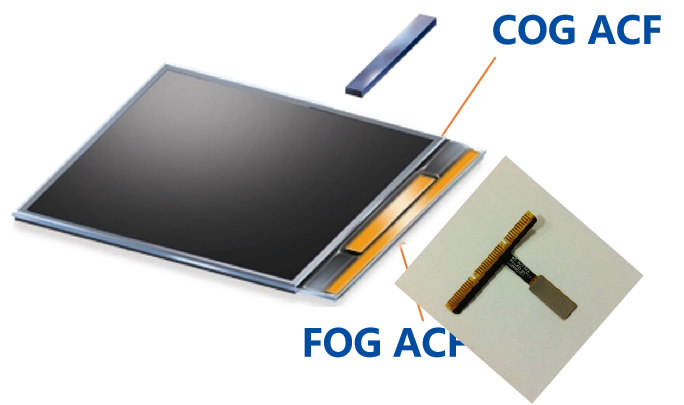

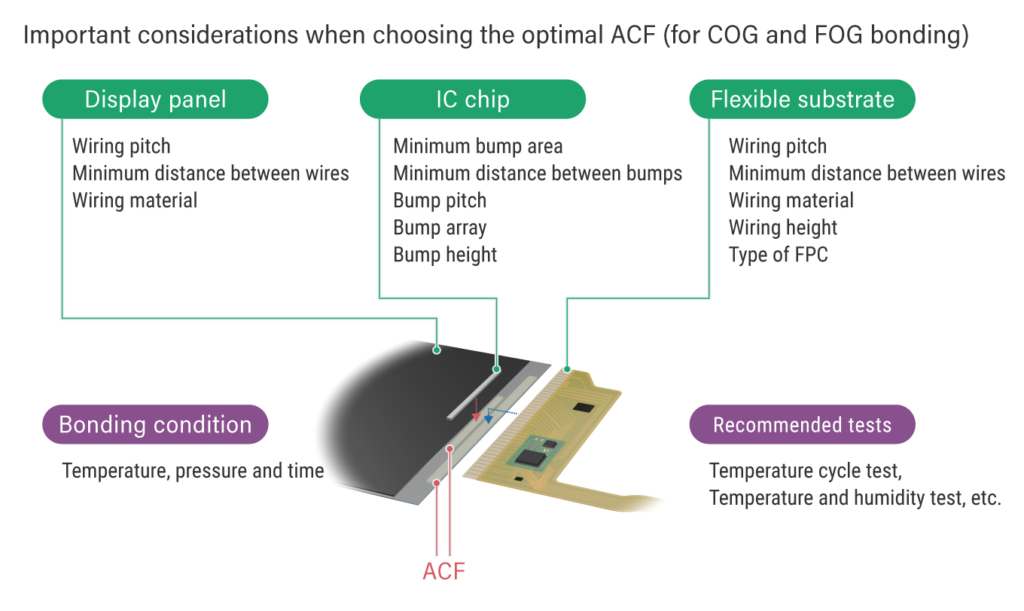

ACFs are mainly used in COGs and FOGs in displays, where ACFs for COGs are used to connect Driver ICs to LCD glass electrodes, and ACFs for FOGs are used to connect FPCs to LCD glass electrodes.

1. Conductive connections:

Used for soldering driver ICs and flexible circuit boards (FPCs) to glass substrates.ACF enables reliable connections between multiple electrodes. Through the hot pressing process, the conductive particles distributed in ACF are arranged under pressure and heat to form conductive paths that connect the circuit board (PCB) to the ITO electrodes on the LCD glass.

2. Insulation function:

Except for the direction of conductivity (perpendicular to the contact surface), ACF has excellent insulation properties and prevents short circuits between lines.

3. Main producing countries:

1. Japanese brands: Hitachi Chemical and Sony occupy about 60-70% of the global market share.

2. Korean brands: occupy 20-30%, mainly in the OLED and small device application field is competitive.

3. Chinese brands: Ningbo Liansen, DCT High-tech Although the proportion of less than 10%, but the growth rate is faster, mainly concentrated in the low-end market.

4. Competition characteristics:

1. Japanese brands are suitable for high-end markets, such as Apple and Samsung supply chains, due to leading technology and high quality.

2. Korean brands focus more on cost-effectiveness and applications in emerging areas.

3. Chinese brands are on the rise, benefiting from domestic TFT-LCD/OLED production capacity enhancement and gradually improving market recognition.

5. Importance of ACF in TFT:

Specific parameters affecting the performance of ACFs (Anisotropic Conductive Films) are mainly related to their constituent materials, structural design and process conditions. These parameters directly affect the conductivity, insulation, adhesion and long-term reliability of ACFs. The following are the main key parameters and their effects:

1. Parameters of conductive particles

Conductive particles are the most important component of ACF, which determines the stability and effectiveness of the conductive properties.

5.1.1 Particle Size:

5.1.2 Particles too small: May not be able to contact effectively, resulting in high contact resistance.

5.1.3 Particles too large: may cause short circuits, especially in fine-pitch applications.

5.1.4 Common range: 3μm-10μm depending on electrode spacing.

5.1.5 Particle Density:

5.1.6 Low Density: Inadequate conductive path reduces the stability of the connection.

5.1.7 High density: prone to short circuits, increasing the difficulty of manufacturing.

5.1.8 Typical densities are designed to be in the range of 5000-25000 particles/mm².

2. Thermal compression time and pressure parameters for conductive particles

5.2.1 Typically in the range of 180°C-230°C to ensure that the adhesive cures and activates the conductive particles to form the connection.

5.2.2 Low temperature: insufficient curing, unstable connection.

5.2.3 Excessive temperature: may damage the electrode or FPC material, and even lead to the destruction of the particle coating.

5.2.4 Common range: 3 to 10 seconds, depending on type of adhesive and hot press equipment.

5.2.5 Too short a time: Insufficient compaction and curing.

5.2.6 The CTE of the adhesive layer needs to be matched with the substrate (e.g. ITO glass or FPC) in order to avoid delamination or open-circuit phenomenon caused by thermal expansion and contraction.

5.2.7 Excessive time: may lead to material deterioration or electrode damage.

5.2.8 Typically between 2 MPa and 4 MPa. Too low a pressure will not form a reliable connection, while too high a pressure will tend to destroy conductive particles or cause short circuits.

Summary:

The key parameters of ACF is a complex multi-variable system involving optimization and matching of particles, adhesive layers and process conditions. For different application scenarios, all TFTs produced by ICP DAS use the brands Hitachi Chemical and Sony to meet the high quality and reliability requirements of TFT-LCDs.